Dongguan Wizbang

Thu 9 Feb 2017 by mskala Tags used: electronics, hardware, music, north-coastHere's another update on what's up with my new life and new business. In general, there's progress being made, but I'm still facing a lot of annoying delays.

Transportation of my possessions from Sweden has now been arranged, and I expect to get those this month. (Original target: last November.) The big issue there is the computer. I really need a fully powered desktop computer to do my office computing and design work, and I'd been counting on having the one that will be in that shipment. Without the big computer, I'm running everything off a little Asus netbook, and although it's holding up remarkably well, it's not really up to some of the things I need to do. The AliBaba Web site, in particular, doesn't work on the small screen, and consumes ridiculous amounts of CPU in the browser, and I need to use that Web site. And the keyboard on the netbook is starting to go. It's well past its expected lifespan. If the letter "s" is missing in ome of the words in this posting, that's why. And, especially after my schedule was set back about three months between the shipping issues, the delay registering my business, and so on, I don't have cash to spare for buying another computer now. I just have to limp along with this one and hope the other one arrives soon.

My corporation is incorporated, that's nice, but now I'm waiting for my GST/HST registration to be processed so that I can collect HST from my customers (whoop-de-doo), and more importantly, I can be reimbursed the HST my suppliers collect from me. I don't want to incur too many large expenses before I have that set up, even though there is some possibility of retroactively getting reimbursements for HST on expenses I incur before the registration is processed. It means I have a steadily growing shopping list to work through once the registration is done. I was told it took 15 business days from when the paperwork was submitted, and it's been more than that, but there's not a lot the people helping me can do about it because it's in the government's hands to process, whenever they do.

I needed to line up suppliers for electronic components, so I took the list of parts I needed for the MSK 010 prototypes, opened up the Web sites of a couple of different possible suppliers, and tried to source each part. When I got to the end of my bill of materials I found about three-quarters of the items were in the Newark Element14 cart: they had the best prices, selection, ease of use on the Web site, and so on. So, I was happily thinking I could make them my main supplier for almost all components. I placed my test order.

Newark failed the test badly. I expected to get most of the parts I'd ordered on January 6 and all of them by January 10. Instead, I received nothing until January 17; I still haven't received some of the items I ordered now, February 9; and I can't realistically expect to ever receive some of them at all. Along the way, almost everything that could go wrong did. Newark decided they needed to check my credit even though eliminating the need for such checks is the point of my having a credit card. Then when I sent them the information they needed for that, they did nothing for a week, and ignored all my attempts to contact them (as well as their own 48-hour deadline). During that week, they didn't reserve the stock, so some of the items I'd ordered which had been in stock when I ordered them, went onto back order or became discontinued.

UPS dropped the first shipment on the back porch of 224 Fictional Avenue while I was at home at the correct shipping address of 226 Fictional Avenue, without knocking on my door, forcing me to search the neighbourhood. (Not the real addresses involved, of course, but these correctly represent the relationship between the real addresses.) Items not in that first shipment have trickled in in a series of small shipments, including one for which I was billed CAD$16 for shipping of a small padded envelope whose contents were worth CAD$14 - and another shipment consisting of a large cardboard box almost entirely full of packing material, containing CAD$4.90 worth of parts that could easily have fit in a small envelope, with no charge for shipping. And so on. I mailed them a hardcopy letter over the weekend; I am not expecting any real response, even though I was very polite and restrained myself from using the phrase "ass with both hands" and similarly colourful language to describe my impression of Newark's operations. So, I have to use other suppliers for components, and they all have their own problems.

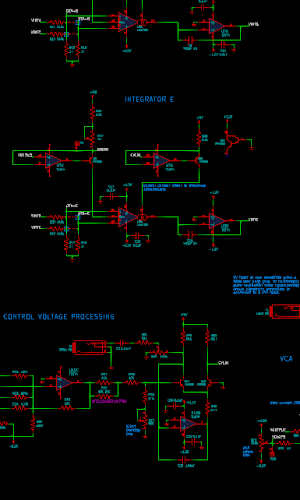

With the prototype parts (including some I ended up ordering from Mouser, next day delivery, to fill in the gaps in the Newark order) I was able to assemble a prototype of my first product... and discover some design issues in it. Well, that's why we make prototypes. But it means I need to do another prototyping cycle before I can go into production.

Another significant issue is the front panel. It's important to the high-quality branding of North Coast that my modules come with real front panels - 2.00mm anodized aluminum with quality printed graphics. Some other manufacturers make do with plastic, or circuit board material (which is laminated fibreglass) but it makes the modules look and feel cheap, and reduces the price they can command.

There are potentially about five different products that can come from one module design, aimed at different levels of do-it-yourself hobbyists. The most expensive option, bottom of the line in terms of user skill, is the fully assembled module, ready to plug into a rack. Next step (cheaper and more advanced) is a so-called "full" kit, with all the parts you need, you use your own tools to assemble it. (My kits won't include solder because people have their own ideas about what kind of solder they want to use; but some manufacturers even supply solder in full kits.) Next is a "partial" kit, which is supposed to contain the parts that are unique to this module or that hobbyists find difficult to obtain in small quantities, but not include generic parts like basic resistors that customers probably have on hand already. After that you can go for "PCB and panel," which is just the printed circuit boards and the aluminum panel - parts that normally must be custom-manufactured, and aren't really practical to do by hand in small quantities. But some people will try to make their own panels by hand, and for those people there may also be an option of buying just the PCBs. Finally, the hidden sixth option is that a real maniac could opt to buy nothing from North Coast, etch his or her own circuit boards from the publicly-available design, and work from there. This is not practical, but people do it.

Now, working our way back down the list, let's look at the economics. It costs me between USD$2 and USD$3 to have a circuit board made in production quantities, there are two needed per module, and customers will happily pay USD$12 each for them. I think this is because customers perceive the PCB as the embodiment of the designer's creativity and development work; so they see buying the PCB from me at a significant markup as the way to support my efforts and as some kind of a moral obligation.

Getting a panel made costs much more than getting a PCB made. If you go to an expensive prototyping place, the PCBs might cost USD$5 instead of USD$2 - you are paying for speed, convenience, and small quantities. There's an expensive prototyping place for aluminum panels, too (Front Panel Express in Seattle, and their parent company Schaeffer AG in Berlin). I paid them USD$31 per unit for my MSK 010 prototype panels - and it normally would have been more, but I was taking advantage of a special discount offer that basically meant they charged me for the small quantity at the rate they would have charged if I were ordering a production run. So, if I did order production quantities, those panels from FPE would cost about USD$31 also.

Now do the math: customers are willing to pay USD$24 for the "PCBs only," which contains two PCBs worth about USD$2.50 each. The "PCB and panel" set, which is what most customers prefer if they're buying one of these two options, contains those same two PCBs, plus a panel that costs USD$31 from Front Panel Express, and customers are willing to pay about USD$36 for that set. Customers are willing to pay about the same amount for a panel as for a PCB, even though the panels cost far more, because they don't perceive the value in a panel. One lesson is that I'd be nuts to offer "PCB and panel" if I had to buy the panels at FPE prices. But, more subtly, even if I don't offer "PCB and panel" I still need to include a panel in my higher-priced options (the kits and the fully assembled modules) and I can't make a living on just selling PCBs even though they sell at a nice margin, because the market for that is too small. And USD$31 for a panel is so much that it would eat significantly into the profit margins on the higher-priced options as well - probably making "partial kit" uneconomic (although there are also other reasons it may not make sense to offer those), harming the margin on "full kit," and even having a noticeable impact on the bottom line for fully assembled modules. So... the consequence is that I just have to get the panels at a much better price than USD$31, one way or another.

Go to the Far East, young man!

I've spent a large part of the last month or so learning a whole lot about the import/export business, as well as Chinese business culture. I've also had to dust off all the mechanical drawing and metalwork I learned as a not-really high school student. This stuff is hard. It's amazing that computer software ever works, of course, but we should also be amazed that when two mechanical things are supposed to fit together, like a lid that goes onto a box, pretty often they actually do fit. I think most people don't understand the amount of work that goes on behind the scenes in making things like that happen.

The way it's done in China is that for any given industry the Communist Party Central Committee or whatever decides the country needs, they'll designate a city for that. Sometimes they build new cities just for specific industries. You've heard me talk before about buying circuit boards from Shenzhen, but that's not just because the one contractor I've used happens to be in Shenzhen; actually all the circuit board contractors are in Shenzhen because Shenzhen is the circuit board city. The machine shop city is called Dongguan. It is three times the size of Toronto.

Individual Chinese machine shops have names like "Dongguan Wizbang Hardware Co. Ltd.," "Dongguan Snafu Hardware Co. Inc.," "Dongguan QRM Hardware Co. Inc. Ltd.," and so on. I have to keep detailed notes on which one is which. Anyway, one can get in touch with these shops via the AliBaba Web site, which is not optimized for viewing on a netbook screen, and send RFQs (Requests For Quotes) to them and then try to make a deal.

AliBaba, like any other large Web site, has developed its own culture, and it's weird. Every company has a contact page. Chinese business is all about the personal relationships, so the contact page will be a personal profile of the person you're supposed to contact - maybe it'll be "Mr. Jing Chang, Senior Sales Manager." (It may be impossible to guess gender from transcribed Chinese names, but they helpfully indicate "Mr." or "Ms." to prevent embarassing mistakes.) And they provide a photo. But they think I'm more likely to send an RFQ if I think I'm talking to an attractive young woman, so the photo next to the name "Mr. Jing Chang" usually depicts a smiling 22-year-old Chinese woman. In one case, it was a photo of three blue-eyed European people in business suits, apparently ripped straight off of a stock-photo site. That's just how things are on AliBaba. And if I write to him/her/them, the reply will almost certainly come back signed by a different name anyway.

I know this guy Luneberg (not his real name) who is a senior professional engineer in the States, and he's kind of an asshole. And knowing him has been inspirational to me in my own recent foray into mechanical engineering, because I figure engineers are pretty much the same the world over. The Dongguan Wizbang Hardware Co. Ltd. is going to hand my RFQ to somebody very much like Luneberg (maybe named Lun Bahg) and either out of sheer engineering cussedness, an effort to save money, Murphy's Law, or even a genuine misunderstanding of my intentions, that person is going to have them tool up and produce whatever possible item least resembles the item I wanted, subject to it being technically within specification. So... I look at my RFQ and ask "What would Luneberg do?" That is, how would he deliberately misinterpret this just to make trouble? If someone like him couldn't possibly find any loopholes in it, then it might be ready to send to Dongguan.

But they still manage to surprise me. One place (actually not in China - most of the places I'm talking to are in Dongguan, but I'm playing the global game now) told me they couldn't meet the mechanical tolerance I had specified. Well, on the one hand, that may not be super-critical. They said they could come close, and it's true I might have specified it tighter than I really needed. On the other hand: the original specification was generous. When I took metal shop class 25 years ago I could probably have hit that tolerance myself on a good day, and I was an inexperienced teenager using equipment that was not new or well-maintained at the time, and hadn't been top of the line when it was new an unknown number of years before that. So something feels wrong here. I wasn't expecting any trouble with the mechanical requirements; any dirtbag shop in Dongguan or wherever ought to be able to do that part. The much harder part, which unfortunately is critical to my application, is the printing.

Another place quoted me a price of USD$50 per unit in production quantities. I was tempted to reply with a cartoon, but instead, I explained politely that since I already had purchased samples at USD$31 from an expensive prototyping shop, and I couldn't afford that much and on production quantities I needed a significantly better price yet for the deal to make any sense, it would probably not be worth their or my time to continue our discussion further.

I don't know. Maybe quoting a ridiculous price is the way, in Chinese business culture, that you politely tell a customer "We don't want to do this job" while allowing him to save face that you didn't actually refuse. Maybe they thought all foreigners are rich and stupid and I really might pay that. Maybe because of tooling costs it's true they would need USD$50 per unit to profit on a job so small as mine. Maybe they didn't understand my specification and thought it was a lot more difficult to manufacture than it really was. Or maybe they wanted to buy the parts from Front Panel Express, have them shipped to Dongguan and then to me, and pocket a profit on the deal, because at that price they could even do that at least until the new regime in the States shuts down trade between the USA and China.

Another place quoted me a suprisingly low price per unit for 50 units, and about 15% more per unit for 200 units. I have email out to them now trying to clarify whether they really intended to say that. I could imagine scenarios where it might possibly make sense (in particular, if they expect to do the smaller order using resources that might otherwise be wasted, like labour at the end of a shift, and the larger order wouldn't fit into such a gap) but it seems more likely that it's a mistake, because that's just not how business usually works. (Edit: response came in while I was writing this. Turns out it was a special introductory price. Which means we need to communicate some more, because I need to know the ordinary everyday not "introductory" price if I'm going to deal with them longer than for just one order. I'm reminded of considerations that apply to dating when one is seeking marriage, but I'm not going to attempt to explain that to my contacts in Dongguan.)

Sidelight: Internet advertising actually does work that way - the price for 1000 clicks is considerably more per click than for 10 at the same quality level. I think it comes about because 1000 clicks at a high quality level in let's say a day is a big enough fraction of the market that the very act of making the order causes clicks to become more scarce and the price to go up. I'm still bitter over the fact nobody has taken seriously my writings on the advertising quantity premium.

Note that the political instability of US trade is already a significant disincentive to my buying from US contractors, and the Trump regime hasn't even done any renegotiating of the deals with Canada in particular yet. They're going to find it increasingly difficult to support the claim that they're creating jobs down there as more and more exporting businesses lose customers to this. It's "dating and marriage" again - I am not just looking to buy 50 panels today, but hundreds of panels per year for as long as I stay in business, and choosing a supplier located in a country that might close its border with Canada during that time is a risk I have to factor into my business decision.

Nobody seems to be able to read my DXF files (mechanical drawings) created with QCad, which is a pretty significant problem. I thought (based on having learned what little I know of mechanical engineering in the 1980s and early 1990s) that the idea was I make a drawing, and a human being looks at the drawing and sets up the machinery to make the part. In that case, it doesn't matter what file format it is, it just needs to be something that can be printed on paper. I ought to be able to lay it all out with a T-square and a technical pen on real paper and scan the result and they ought to be able to read that. I might even score some style points with Luneberg or his trans-Pacific counterpart for actually being able to do everything old-school like in the days when men were real men and India ink was real India ink. I'm not just some "maker" kiddie playing with toys. But in 2017, the machine shops want to dispense with the humans and feed the drawings more or less directly into the machines, and in that case, file format really matters a lot. The data has to not only look right to a human eye but be so precisely conformant to the (not really documented, de facto) commercial format standard that the LUN-B3R6 Moderate Precision Manufacturing Robot is unable to compute a way to manufacture anything other than what I want.

I shouldn't have been surprised, I suppose, because I've been designing circuit boards and producing Gerber files for direct input into the circuit-board robots, for years already. The sheet metal machines work on the same principle. They want Really Authentic-Looking DXF files such as come out of AutoCAD, not QCad. And I'm not about to buy a new computer just to run AutoCAD (because it won't work on my existing systems, even the big one that's en route from Sweden let alone this little netbook) and then pay $220/month to AutoDesk to license their product as "software as a service," an act which would be morally repugnant even if I could afford it. And then, at least one place doesn't even want a two-dimensional DXF file. They want a three-dimensional IGES file.

So I had to learn what an IGES file even is. Now I'm compiling prerequisites of the prerequisites of FreeCAD, which claims to be able to produce IGES files. I'm two days into that project now. The netbook really is not up to the task - and it's partly because I'm on this little netbook that I can't "just" download a binary distribution, because those are all built for bigger systems. And of course once I get the software to run, if that ever happens, I'll have to learn a bunch of new skills to use it. On the plus side, having 3D drafting capability will be quite useful in future projects - which is why I didn't just tell the contractors who wanted machine-readable 3D drawings to take a hike.

Don't get me started about Pantone numbers.

And of course nobody was answering their email last week because it was Chinese New Year.

Much of this update may sound like complaints, but I'm talking about the things that are at the top of my mind and those tend to be the problems I'm working on rather than the aspects in which I find contentment. I remain glad to be in Toronto. I cannot say that it's exactly home - there is no place for me that's really home and I'm not sure there ever will be, for reasons that may be apparent from a close reading of some lines in this excellent song. But Toronto is the most homelike place I've been.

I daily find reasons to be glad that I am out of the academic game.

0 comments